In today’s vehicles and off-grid setups, having power that’s dependable and consistent is non-negotiable. As battery tech has evolved, it’s become easier to get efficient, reliable energy for a wide range of equipment. You may have come across the term “AGM battery” and asked yourself: What exactly is an AGM battery, and why are so many people switching to it? AGM (Absorbent Glass Mat) batteries are a type of valve-regulated sealed lead-acid battery (VRLA). They’re known for strong performance, low upkeep, and a sealed design that makes them a practical choice for things like automotive start-stop systems, renewable energy storage, and communications equipment.

This guide breaks down what AGM batteries are, how they operate, where they’re used, and what to look for when buying one—so you can decide whether an AGM battery is the right fit for your setup.

What Is An AGM Battery? What Type Of Battery Is It?

An AGM battery (short for absorbed glass mat / absorbed glass fibre separator battery) is a valve-regulated sealed lead-acid (VRLA) battery.

This technology emerged in the late 20th century and was first engineered for aviation and defence uses that demanded a sealed, high-safety power source. Because it delivered strong output with fewer maintenance headaches, it quickly moved into civilian markets. Today, AGM batteries are commonly used in modern automotive start-stop systems, backup power for data centres, and renewable energy storage applications.

Even though AGM batteries and standard lead-acid batteries fall under the broader lead-acid category, AGM designs differ from traditional flooded lead-acid batteries that rely on free-flowing liquid electrolyte.

Instead of liquid sloshing around inside the case, AGM batteries use an absorbent separator (AGM separator) made from ultra-fine glass fibres. With porosity typically above 90%, the separator holds the electrolyte within its fibre network, leaving essentially no “free” liquid in the battery. This “starved electrolyte” approach reduces leak risk and supports internal oxygen recombination, which is a big reason AGM batteries can be sealed and maintenance-free.

AGM batteries typically use high-purity sulphuric acid electrolyte, with density often in the 1.29–1.31 g/cm³ range—usually a bit higher than many flooded lead-acid designs. A key detail is that AGM separators intentionally leave roughly 10% of pores unfilled. Those tiny air channels allow oxygen produced at the positive plate to travel to the negative plate, enabling internal gas recombination. Because the system recombines most gases back into water, AGM batteries lose very little water during normal charge/discharge, which helps extend service life.

Compared with conventional flooded lead-acid batteries, AGM batteries are a meaningful step forward. Flooded batteries often need periodic electrolyte level checks and topping up with distilled water. AGM batteries remove that routine by using an absorbent mat design plus a valve-regulated sealed structure. Their sealed construction also improves installation flexibility: they can be mounted on their side and can even be placed upside down (though long-term inverted use still isn’t recommended). That flexibility is helpful when space is tight.

The table below highlights the practical differences between AGM batteries and traditional flooded lead-acid batteries so you can compare them at a glance:

Characteristics

AGM battery

Traditional flooded batteries

Electrolyte status

Held in a glass-fibre mat separator (starved electrolyte)

Free liquid electrolyte (flooded)

Maintenance requirements

Sealed case, generally maintenance-free

Needs periodic checks and water top-ups

Installation position

Multiple orientations possible (avoid long-term upside-down mounting)

Typically upright only

Oxygen recombination efficiency

Very high; minimal water loss in normal use

Lower; water loss during charging is common

Seismic performance

Strong resistance to shock and vibration

Moderate; vibration can loosen active material over time

What Are The Components Of AGM Batteries? How Does It Work?

To see why AGM batteries perform the way they do, it helps to look at their internal build. Their construction is what enables the sealed design, strong output, and durability. The main parts include the positive and negative plates, the AGM separator, the electrolyte, a pressure-regulated safety valve, and the outer case. Each piece is engineered to support efficiency, safety, and reliability. Here’s what each component does.

Plate system: This is where energy is stored and released. Like other lead-acid batteries, AGM batteries use lead dioxide (PbO₂) on the positive plate and sponge lead (Pb) on the negative plate. However, AGM batteries commonly use higher-purity lead and tighter manufacturing tolerances, which can improve energy delivery and cycle life. Grid alloys are typically designed for better corrosion resistance and conductivity. AGM plates are often thicker and more tightly packed than many conventional flooded batteries, helping with deep-cycle performance and overall physical stability.

AGM separator: Made from ultra-fine glass fibres formed into a high-porosity 3D network, this separator prevents short circuits by keeping plates apart, and it also acts like a sponge. Through capillary action, it holds electrolyte in place so it doesn’t flow freely. The separator is engineered to retain the “right” amount of electrolyte while leaving about 10% of pores open. Those open pores create a pathway for oxygen to move between plates during charging. Glass fibre diameter is usually around 1–3 microns, creating a large surface area that improves electrolyte retention and ion movement.

Electrolyte system: In an AGM battery, electrolyte is mostly absorbed into the separator and plate structure, so it behaves more like a semi-immobilized system than a sloshing liquid. This reduces leak risk and improves the contact area between plates and electrolyte, which helps lower internal resistance. Lower resistance allows AGM batteries to deliver higher burst current, which matters for starting and stop-start operation (including certain golf cart and utility vehicle use cases). Electrolyte volume is carefully calculated to support reactions while preserving space for gas diffusion.

Safety valve: AGM batteries rely on a pressure-regulated valve to maintain safe internal conditions. If internal pressure rises above a set threshold (often around 15–30 kPa), the valve vents excess gas to prevent casing damage. Once pressure returns to normal, the valve reseals to limit air entry. This valve-regulated setup supports internal oxygen recombination while keeping operation cleaner and safer.

The table below summarizes the key structural parts of an AGM battery and what each one contributes:

Structural components

Materials/Properties

Functions

Positive plate

Lead dioxide (PbO₂)

Positive active material for electrochemical reactions

Negative plate

Sponge lead (Pb)

Negative active material for electrochemical reactions

AGM separator

Ultrafine glass fiber, porosity >90%

Holds electrolyte and provides oxygen diffusion pathway

Electrolyte

Aqueous sulfuric acid solution (density 1.29-1.31 g/cm³)

Ionic conductor involved in electrochemical reactions

Safety valve

Precision pressure regulator

Manages internal pressure to prevent overpressure or vacuum

So how do these design choices translate into real performance during charging and discharging?

During discharge, lead dioxide at the positive plate and sponge lead at the negative plate react with sulphuric acid electrolyte to form lead sulphate and water—this is the same core chemistry as other lead-acid batteries. During charging, the reaction reverses and restores the original active materials.

What sets AGM apart is what happens later in the charging process. Once charging reaches roughly 70% state of charge, oxygen begins forming at the positive plate. That oxygen travels through the dry pore channels in the separator to the negative plate, where it reacts and ultimately converts back into water through a recombination pathway. This oxygen cycle greatly reduces electrolyte loss and supports the sealed, maintenance-free operation AGM batteries are known for.

Because the electrolyte is held in place by the glass mat, AGM batteries are generally less prone to electrolyte stratification. They also tend to resist water loss better in warmer conditions compared with many flooded designs. As a result, AGM batteries often handle a broad operating range—commonly around -30°C to +60°C (-22°F to +140°F). That wide range can be useful in Canadian conditions, where winter cold starts are common and equipment may also face summer heat in enclosed compartments.

What Are The Advantages Of AGM Batteries?

AGM batteries have gained ground in many applications because they combine practical durability with strong electrical performance. Their benefits aren’t only about output—they also show up in safety, environmental fit, and service life, which matters as modern vehicles and power systems demand more from their batteries.

Deep Cycle Performance: Compared with basic starting flooded batteries, AGM batteries use thicker plates and refined active material blends, helping them tolerate deeper discharge cycles (often up to about 80% DOD) without the same rapid degradation. Flooded starting batteries can lose performance quickly after repeated deep discharges, but AGM construction helps keep active material in place and reduces shedding. In real terms, many quality AGM start-stop batteries can handle significantly more deep-cycle events than traditional flooded batteries, which is why AGM is often used in renewable energy storage and auxiliary power systems, including certain electric golf cart setups.

High discharge power: AGM batteries typically have lower internal resistance thanks to the tightly compressed plate/separator construction and fine glass mat. Lower resistance improves burst current delivery and reduces energy lost as heat during high-current demand. For starting applications, AGM batteries can deliver strong cold cranking output in low temperatures, improving start reliability.

Fast charging capability: AGM designs generally accept higher charge current more efficiently than many flooded batteries, with reduced risk of electrolyte stratification. That makes them useful in scenarios where recharge time matters—like frequent start-stop driving, fleet vehicles, or systems that need quicker turnaround between uses.

Ultra-long float life: This is one of the biggest reasons AGM is popular for standby and backup power. In UPS systems and telecom sites, batteries often sit on float charge for long periods and must be ready instantly. AGM’s sealed design and internal recombination reduce stratification and water loss—two factors that commonly shorten float life in flooded batteries. Many high-quality AGM batteries are designed for roughly 8–12 years of float service at 25°C (77°F), often outperforming standard flooded batteries in similar conditions. That can lower long-term upkeep and replacement costs for backup systems.

Safety and environmental protection: AGM batteries are sealed and valve-regulated, which helps prevent acid leakage and reduces acid mist. If overcharging occurs, the pressure valve vents to relieve excess pressure and lower the chance of case rupture. AGM batteries also tend to produce low hydrogen emissions under normal operation (often cited around <4 ml/Ah), helping make them suitable for tighter spaces such as RV compartments (while still following proper ventilation practices). From a lifecycle standpoint, the sealed structure also reduces mess and contamination risk during use and routine handling.

Physical stability: The glass mat provides structural support that helps reduce plate movement and damage from vibration. Because there’s no free electrolyte to spill, AGM batteries can be installed more flexibly (again, aside from long-term inverted use), which can simplify packaging in boats, motorcycles, ATVs, and space-limited equipment bays.

AGM vs. Lead-Acid and Lithium-Ion Batteries

If you’re deciding between battery types, comparing the core specs side-by-side can make the choice clearer. The table below contrasts AGM batteries with flooded lead-acid and lithium-ion options.

Feature

AGM Battery

Flooded Lead-Acid Battery

Lithium-Ion Battery

Maintenance

Maintenance-free

Requires regular water top-ups

Maintenance-free

Positioning

Any position (sideways, upside down)

Upright only

Any position

Deep Cycling

Excellent (1,000-1,500 cycles)

Limited (~500 cycles)

Superior (2,000-5,000 cycles)

Charging Speed

Fast due to low internal resistance

Slower charging

Very fast charging

Vibration Resistance

High resistance to vibrations

Moderate, prone to plate damage

High resistance

Weight

Moderate (~44-66 lbs (~20-30 kg) for 12V 100Ah)

Heavy (~55-77 lbs (~25-35 kg) for 12V 100Ah)

Lightweight (~22-33 lbs (~10-15 kg) for 12V 100Ah)

Lifespan

4-7 years

3-5 years

8-10 years

Cost

CAD $200-$550 (varies by size/brand)

CAD $140-$280, most affordable

CAD $400-$1,350, higher upfront cost

Energy Density

30-40 Wh/kg

25-35 Wh/kg

100-150 Wh/kg

What is an AGM battery vs lead acid? Compared with standard flooded lead-acid batteries, AGM batteries typically charge more efficiently, handle vibration better, and are spill-resistant—making them safer and easier to install in more places.

Compared to lithium-ion batteries, AGM batteries can be a more budget-friendly option for many automotive and marine uses, but they’re heavier and usually don’t last as long (often around 4–7 years versus roughly 10–15 years in many lithium setups). Lithium batteries also offer much higher energy density (100–150 Wh/kg versus about 30–40 Wh/kg), which can matter a lot in weight-sensitive applications like electric golf carts or Class A, B, and C motorhomes.

Where Are AGM Batteries Used?

AGM batteries support a wide range of equipment because they combine deep-cycle capability, strong discharge performance, and a sealed design that’s generally safer to live with. You’ll see AGM batteries used across automotive, communications, renewable energy, and emergency power applications.

Knowing the most common AGM use cases can help you match battery type to real-world demands instead of just picking based on price.

Vehicle Start-Stop System

As automakers push harder on fuel efficiency and emissions targets, start-stop technology has become more common. The system shuts the engine off during short stops and restarts quickly when it’s time to move again, which can cut fuel use in city driving (often cited around 5%–10%, depending on traffic patterns).

This kind of operation is hard on batteries. The battery must deliver repeated high-current starts and then accept charge quickly during short driving intervals—while also supporting growing onboard electronics loads.

AGM batteries are well suited here because they tolerate cycling better, accept charge efficiently, and handle vibration. European brands like Mercedes-Benz and BMW have used AGM widely for start-stop applications, and many other manufacturers across Japan, Korea, and North America have also adopted AGM in various models. In practice, start-stop vehicles typically use higher-capacity AGM batteries (often in the 70–100Ah range) to cope with frequent restarts and accessory loads.

High-end motorcycles and specialty vehicles

Premium motorcycles, ATVs, snowmobiles, and performance vehicles often need batteries that handle vibration and allow tighter packaging. AGM batteries perform well under heavy vibration and are less likely to suffer from electrolyte stratification issues common in flooded batteries. Their sealed build also allows more flexible mounting angles, giving designers more freedom in compact vehicle layouts.

Renewable Energy Storage Systems

In off-grid solar and small wind systems, batteries must smooth out variable generation by storing energy and delivering it steadily—often with frequent cycling. AGM batteries are a solid fit for small to mid-size systems because they’re sealed, require minimal routine upkeep, and generally tolerate partial state of charge (PSoC) operation better than many flooded options. For unattended systems—like solar street lights or remote communications repeaters—avoiding water top-ups can reduce maintenance trips and operating costs.

Uninterruptible Power Supplies (UPS) and Telecommunications Backup Power

Data centres, medical equipment, telecom base stations, and industrial control gear rely on power continuity. When the grid drops, the battery bank must take over immediately. AGM batteries are widely used in these standby roles because of their float performance, reliability, and low-maintenance operation. In telecom, the compact build helps fit more capacity into limited cabinets, while the sealed structure reduces corrosion risk inside enclosed spaces. These systems often use multiple batteries in series strings, so stable voltage behaviour and consistency between units plays a big role in overall lifespan. In many UPS configurations, AGM batteries can provide several minutes of runtime—often enough to safely save data or bridge power until a generator comes online.

Marine and RV Power Systems

Marine environments are tough on electrical gear because of moisture and salt exposure. AGM batteries help reduce corrosion issues because they’re sealed and don’t vent acid mist the way some flooded systems can. On boats, AGM batteries can support both engine starting and house loads like navigation electronics and lighting, while handling ongoing vibration from operation.

For RV use, AGM batteries are a common option for powering living loads. Their sealed design makes them safer to place near living areas, and they can handle repeated cycling on the road. Some RV setups pair AGM batteries with solar charge controllers for more self-sufficient off-grid camping.

Electric Vehicles and Industrial Applications

AGM batteries are also used in equipment like electric wheelchairs and certain golf carts because they handle deeper discharge better than many basic flooded starting batteries, and they don’t require routine water maintenance. In medical and safety systems—portable medical devices, emergency lighting, alarms—AGM batteries are frequently chosen for leak resistance and reliable standby performance.

If you want a battery that improves on traditional flooded lead-acid without jumping to lithium pricing, AGM can be a practical middle ground, even though upfront costs are usually higher. Deep-cycle capability and sealed operation can make sense across many real-world applications.

If you’re planning to upgrade an RV, electric golf cart, marine electronics, or a home solar system, you can also purchase Vatrer 12V, 24V, 36V, and 48V lithium-ion batteries. Our batteries are equipped with a battery management system (BMS), low-temperature protection, and self-heating features. We also offer small-size batteries to suit your installation space. Vatrer batteries offer up to 4,000 deep cycles and zero maintenance, offering excellent value for money.

How to Choose an AGM Battery?

Choosing an AGM battery for a vehicle, boat, RV, or solar system comes down to matching the battery to how you actually use power. The goal is reliable performance, decent service life, and sensible long-term value. Here are the main factors to check before you buy.

Reserve Capacity and Power Requirements

Reserve capacity tells you how long a battery can supply a set current before it’s discharged, and it’s commonly referenced in ampere-hours (Ah). For example, a 100Ah battery could theoretically deliver 5 amps for about 20 hours under ideal conditions. When selecting a battery for RV living loads or vehicle starting, lower internal resistance matters because it helps reduce heat buildup during charging and discharge, improves efficiency, and lowers overheating risk. Review the battery’s reserve capacity and make sure it aligns with your real power draw—for example, many small solar installations use around 50–100Ah, while start-stop vehicles commonly land around 70–90Ah depending on electrical load and OEM spec.

Lifespan and Usage Patterns

AGM batteries often last about 4 to 7 years, but real life depends heavily on how they’re used. Regular deep discharges (well below 50% capacity) can shorten lifespan, and heat is another major factor. In warmer environments or enclosed compartments, batteries can age faster. For example, an AGM battery used daily for deep cycling in an off-grid setup may trend closer to 4 years, while one used for lighter cycling in a moderate climate may reach closer to 7 years. Check the cycle rating (often around 1,000–1,500 cycles at 50% depth of discharge) to understand what the battery is built to handle.

Compatibility with Your System

Confirm the AGM battery matches your system requirements—voltage (12V is common for RV and marine) and current demand. Start-stop vehicles, for instance, need batteries that handle frequent cycling and high discharge rates, which is a core AGM strength. Check the owner’s manual (or ask a technician) so you don’t end up with an undersized or mismatched unit. Also confirm your charging system supports AGM charging profiles. A charger designed only for flooded lead-acid may run the wrong voltage profile, leading to overcharge or undercharge and shorter service life.

Safety and Certifications

Prioritize true sealed, spill-resistant AGM batteries if you’re installing in tighter compartments (boats, RVs, enclosed equipment bays). Look for recognized certifications such as UL or CE, which indicate the battery has been tested against safety and performance requirements. A UL-listed battery, for example, typically signals tested protection related to short circuits and safe operation within defined limits.

Cost-Benefit

In Canada, AGM batteries commonly fall around CAD $200 to $550 depending on capacity and brand. Flooded lead-acid options are usually cheaper (often around CAD $140 to $280), while lithium can be higher upfront (often CAD $400 to $1,350+ depending on chemistry and features). The value argument for AGM is often about reduced upkeep and better durability in vibration or cycling conditions. Over 4–7 years, saving time on maintenance and avoiding early failures can make AGM worthwhile. If your use is light and conditions are easy, a lower-cost flooded battery may still be adequate.

If you have enough budget, in addition to AGM batteries, you can also choose Vatrer RV lithium batteries and golf cart lithium batteries. Our batteries comply with international certifications.

How to Maintain Your AGM Battery?

AGM batteries are often described as maintenance-free, but good habits still make a difference. Proper use and storage can help prevent early failure and reduce how often you need replacement.

Installation Location: Even with a sealed design, avoid placing AGM batteries in high-heat areas. Excessive ambient temperature (above about 60°C/140°F) accelerates ageing. For vehicles with start-stop systems, consider checking battery state of health (SOH) every two years or around 30,000 km. A diagnostic tool can read internal resistance (often expected under about 5 mΩ) and estimate usable capacity (ideally above 80% of rated capacity).

Storage and Maintenance: If the battery will sit unused, store it fully charged (resting voltage typically ≥12.7V) and recharge about every three months. AGM self-discharge is usually low (often around 3%–5% per month), but heat can increase that rate. AGM batteries should not be opened or topped up with water—water loss in normal service is minimal, and adding liquid can disrupt the internal oxygen recombination balance.

Conclusion

Once you understand how AGM batteries are built and where they perform best, it’s easier to choose the right battery for your needs. AGM batteries generally handle vibration better than traditional flooded batteries, and their sealed, low-maintenance design makes them a practical power option for many drivers and system owners.

That said, if you’re prioritizing low weight and longer service life for RVs, golf carts, or home solar storage, lithium batteries are often the more appealing upgrade.

Vatrer offers high-performance lithium-ion batteries, such as the 12V 100Ah LiFePO4 battery, which weighs only 24 lbs, making it lighter than the 60 lbs of an AGM battery of the same size, and boasts over 4,000 cycles. Vatrer batteries are ideal for RV, marine, and solar applications, ensuring efficiency and sustainability.

FAQs/People Also Ask

Can i Use An Agm Battery In a Vehicle Not Originally Designed For It?

In many cases, yes—you can swap a flooded lead-acid battery for an AGM battery, but you need to confirm the charging system is compatible. AGM batteries prefer the correct charging voltage (often about 13.8–14.4V during charging) so they don’t end up overcharged or undercharged.

Check the alternator output and charging specs in your owner’s manual or ask a qualified mechanic. Older vehicles may require a voltage regulator adjustment to stay within the right range.

Also verify fitment: the case size and terminal layout must match your battery tray and cables. When the system is compatible, AGM can improve reliability thanks to better vibration resistance and stronger cycling performance. If you’re unsure, professional installation is a safer route.

Are AGM Batteries Safe To Use Indoors?

Yes—AGM batteries are generally considered safe indoors because they’re sealed and spill-resistant, which limits electrolyte leaks and keeps hydrogen output low (often cited at less than 4ml/Ah under normal conditions).

Unlike flooded lead-acid batteries, they don’t typically produce acid mist, which makes them a common pick for RV living areas or indoor home backup systems. Even so, install them in a space with some ventilation, especially to handle any small amount of gas that could be released if the battery is overcharged.

Choosing a battery with UL or CE certification adds extra confidence. Avoid placing it close to heat sources (above 60°C/140°F) to reduce thermal stress.

Can I Mix AGM and Lead-Acid Batteries In The Same System?

It’s generally not a good idea to mix AGM batteries with flooded lead-acid batteries in the same bank. AGM batteries have different internal resistance and charging targets (often 13.8–14.4V) compared with many flooded batteries (often closer to 14.4–14.8V).

When mixed, one type can be pushed into overcharge or undercharge, which reduces lifespan and performance. In multi-battery systems like solar storage, mismatched charging can speed up failure.

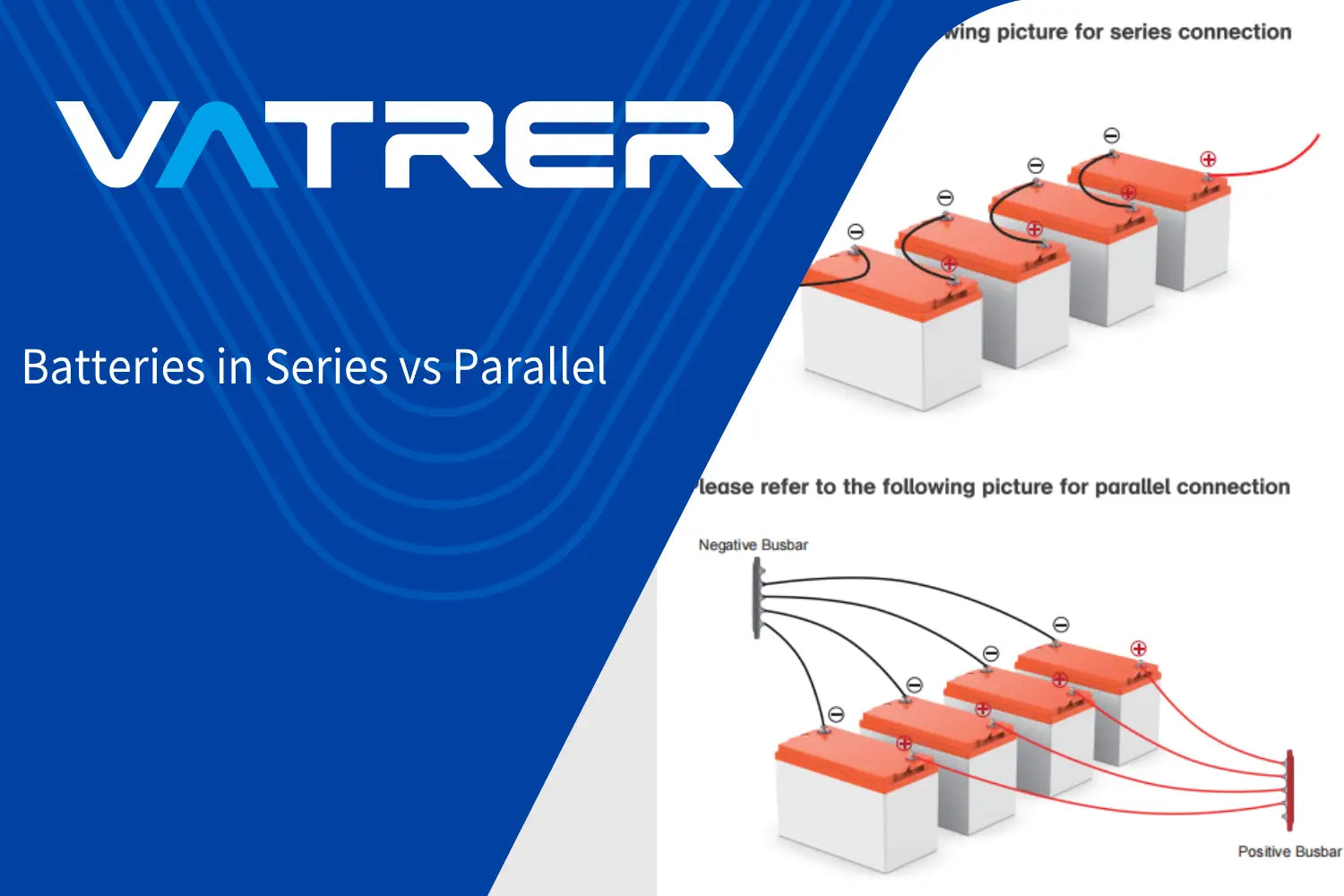

For best results, use matching AGM batteries in series/parallel, and set your charger or charge controller to an AGM profile.

How Do i Know If My AGM Battery Is Fully Charged?

The simplest check is voltage with a multimeter. A fully charged 12-volt AGM battery typically reads about 12.7–12.9V at rest (no load, no charger), measured at around 25°C (77°F).

If it’s reading below roughly 12.4V at rest, it likely needs charging. Use a charger with an AGM setting so it follows the right charge stages (including float). Avoid overcharging—sustained voltage above about 14.8V can trigger the pressure valve and contribute to water loss. Checking state of charge during storage is a good way to extend service life.

What Should i Do If My AGM battery Won’t Hold a Charge?

If an AGM battery won’t hold charge, start by checking resting voltage. A reading below about 12.0V can indicate a severe discharge or a failing battery. Try charging with an AGM-compatible smart charger—ideally one with a reconditioning mode that can help reduce sulphation (lead sulphate crystal buildup on plates).

If the battery doesn’t improve after roughly 24–48 hours of appropriate charging, it may be near end of life (often 4–7 years, depending on use). Check terminals for corrosion and confirm tight connections. If it’s still within warranty (often 1–3 years), contact the manufacturer. Otherwise, replace it with a suitable AGM or lithium option that matches your system’s current demand.

What Happens If i Overcharge An AGM Battery?

Overcharging—especially with a charger not suited for AGM—can create excess gas and pressure inside the battery. When pressure rises too far, the safety valve vents to protect the case.

That venting can lead to moisture loss and reduced electrolyte effectiveness, shortening battery life. For example, charging above about 14.8V can stress the glass mats and plates over time. To reduce risk, use an AGM charger (or AGM mode) that limits absorption voltage to around 14.4V and maintains an appropriate float stage. This is especially important in marine or RV systems where charging sources can vary.

Are AGM Batteries Suitable For Extreme Cold Climates?

AGM batteries generally handle cold well (often down to about -30°C/-22°F) because the electrolyte is held in place by the glass mat, which helps prevent concentration shifts and reduces freezing risk compared with some flooded setups.

That said, cold still reduces usable capacity (often around ~20% less at -18°C/0°F). Keeping the battery fully charged (around 12.7–12.9V at rest) helps performance, and a discharged battery is more likely to freeze.

For winter use, pick an AGM battery with an appropriate cold cranking amps (CCA) rating (often 600–800 CCA for many passenger vehicles, depending on engine size). Store spare batteries in a ventilated area above freezing when possible.

How Do i Know If My AGM Battery Is Compatible With My Solar Charge Controller?

Check whether your charge controller supports AGM charging profiles. The controller should be able to deliver the correct settings—often around 13.8–14.4V for absorption and 13.2–13.6V for float.

Most modern MPPT and PWM controllers allow battery type selection or custom voltage settings. Confirm battery voltage (commonly 12V) and capacity (often 50–200Ah) match your energy needs. For example, a 100W solar panel paired with a 100Ah AGM battery typically calls for a controller rated at least 10A. Incorrect voltage settings can shorten battery life, so if you’re unsure, consult the controller manual or a solar technician.

Do i Need To Use a Battery Charger Designed For AGM Batteries?

To ensure compatibility, check your solar charge controller's settings for AGM battery support, as it must deliver the correct charging profile (typically 13.8-14.4V for absorption and 13.2-13.6V for float).

Yes, it’s strongly recommended. AGM batteries are sealed lead-acid (SLA) batteries and they’re sensitive to charging voltage. A smart charger designed for AGM (or a charger with a true AGM mode) helps keep charging within safe limits and supports longer service life.

Many conventional flooded lead-acid chargers can run too high (sometimes above 14.8V). AGM batteries typically prefer around 14.4V for absorption and about 13.2–13.6V for float. Too much voltage can cause:

Battery swelling or elevated internal pressure

Electrolyte drying over time

Reduced service life