Table of Contents

- Understanding Golf Cart Batteries

- Feasibility of Using 4 12-Volt Batteries in Series

- What Are The Risks Of Using 4 12V Lithium Batteries In a 48V Golf Cart?

- Wiring Challenges for 48-Volt Golf Cart Battery Systems

- Will Using 4 12V Lithium Batteries Affect The Performance Of The Golf Cart?

- What Are Some Alternative Solutions For 48V Golf Cart Batteries?

- Conclusion: Choosing the Best Battery System for Your Golf Cart

For golf course managers seeking reliable Yamaha electric golf cart batteries or recreational owners upgrading an EZGO golf cart battery, a common question is: Can 4 12-volt batteries power a 48-volt golf cart? In this article, we'll discuss lithium battery voltage compatibility, wiring, performance impacts, and practical alternatives to help you make an informed decision, ensuring your golf cart gets the best performance and longest lifespan while maintaining safety.

Understanding 48-Volt Golf Cart Battery Systems

Golf carts typically operate on 36-volt or 48-volt electrical systems, with 48-volt setups common in models like Club Car Precedent batteries or EZGO golf cart battery configurations.

For example, Club Car Precedent models often use six 8-volt lead-acid batteries, while EZGO RXV supports 4 12-volt batteries or a single 48V lithium pack.

According to a Battery University report on the lithium battery industry, traditional lead-acid batteries have an energy density of 30-50 Wh/kg, while lithium-ion batteries offer an energy density of 150-200 Wh/kg, are up to 50% lighter, and can undergo 2,000-5,000 charge cycles, compared to just 500-1,000 for lead-acid batteries.

Typically, a 12-volt lithium battery operates within a 10V (discharge cutoff) to 14.6V (fully charged) range, so four in series fluctuate between 40V and 58.4V. This must align with the cart's motor and controller, designed for 42V-54V to ensure optimal performance.

Feasibility of Using 4 12-Volt Batteries in Series

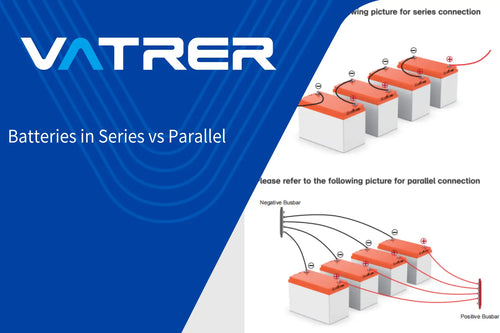

In an electric golf cart's powertrain, the battery pack's voltage configuration is a key factor in determining the vehicle's proper operation. To understand the feasibility of using 4 12V lithium-ion batteries in a 48V golf cart, it's first necessary to understand the basic principles of lithium-ion battery series connection and their voltage characteristics.

Unlike traditional lead-acid batteries, lithium-ion batteries offer a more stable voltage output curve and higher energy density, which offers significant performance advantages but also imposes stricter configuration requirements.

Voltage compatibility issues

When multiple batteries are connected in series, that is, the positive and negative electrodes are connected in sequence, the total voltage of the entire battery pack is the sum of the voltages of each single battery, while the capacity (Ah) remains unchanged. This means connecting 4 12-volt batteries in series (positive to negative) yields a nominal 48V system, as voltages add ((12V × 4 = 48V) while capacity (Ah) remains constant.

This setup is theoretically suitable for a 48V golf cart battery system. However, practical considerations go beyond simple voltage stacking. Lithium-ion batteries typically operate within a range rather than a fixed value.

For example, a nominally 12V lithium-ion battery can actually fluctuate between 10V (discharge cutoff voltage) and 14.6V (charge saturation voltage). This means that a battery pack consisting of four such cells connected in series could have an actual operating voltage range of 40V to 58.4V, placing high compatibility requirements on the golf cart's motor and controller.

Characteristics of different battery types

Different types of lithium batteries also have different voltage characteristics. Commonly used lithium batteries for golf carts include lithium iron phosphate (LiFePO4) and ternary lithium (NCM/NCA). Their voltage platforms and charge-discharge curves vary. The nominal voltage of a single lithium iron phosphate battery cell is 3.2V (a 12V battery pack typically consists of four cells connected in series), with a full-charge voltage of approximately 3.6-3.65V and a discharge cutoff voltage of approximately 2.5V. These parameters for ternary lithium batteries are higher. This difference can affect the actual performance of a series configuration, especially when the battery management system (BMS) settings are mismatched with the battery type.

Battery consistency issues

Since the current in the series circuit is the same, variations in internal resistance, capacity, or state of charge (SOC) among the individual battery cells can lead to overcharging or overdischarging of some cells during the charge and discharge process. This long-term trend accelerates battery aging. Therefore, when connecting 4 independent 12V lithium batteries in series, ensure they are of the same brand, model, and batch, preferably specifically designed for series connection, and operate at the same initial SOC whenever possible.

Therefore, it's theoretically feasible to use 4 12V lithium-ion batteries in series in a 48V golf cart. However, practical considerations include voltage fluctuation range, battery type matching, consistency, and BMS compatibility. For golf cart owners without specialized knowledge, this self-assembled configuration carries certain risks, and opting for a specially designed 48V lithium-ion battery pack is a more reliable option.

What Are The Risks Of Using 4 12V Lithium Batteries In a 48V Golf Cart?

Connecting 4 12V lithium-ion batteries in series to create a 48V system in a golf cart presents numerous potential issues and risks that require vigilance. These risks could not only affect vehicle performance but also endanger safety. Understanding these risks is crucial for making informed decisions.

a Chain Reaction Caused By Battery Inconsistency

Even when using the same brand and model of 12V lithium-ion batteries, individual battery cells can exhibit subtle variations in actual performance parameters due to differences in production batch, usage history, ambient temperature, and other factors.

This inconsistency is amplified during the series charging and discharging process. Smaller cells can fill or discharge before others, resulting in some cells in the battery pack being overcharged while others are undercharged, and some cells being overdischarged while others still have charge.

Over time, this performance discrepancy between cells will grow, creating a vicious cycle that significantly reduces the usable capacity and cycle life of the entire battery pack.

However, 48V integrated lithium-ion battery packs can effectively mitigate this problem through rigorous cell selection and matching and an integrated battery management system (BMS), something that is difficult to achieve with a self-assembled four-cell 12V series configuration.

Battery Management System (BMS) Compatibility

Most standalone 12V lithium battery modules are designed with their own BMS, which is primarily designed to protect a single 12V battery. When multiple such batteries are connected in series, the lack of coordination between the BMSs can lead to asynchronous protection.

For example, if one battery disconnects due to reaching the over-discharge protection threshold while the other batteries are still discharging, the resulting circuit interruption could cause a high-voltage arc or damage the controller. Alternatively, during charging, one 12V battery could prematurely trigger overcharge protection and stop charging while the other batteries are not yet fully charged, resulting in uneven charging.

In contrast, a single 48V lithium battery pack uses a unified BMS to monitor all individual cells, enabling precise charge and discharge control and protection, and providing greater safety.

System Connection Reliability

Connecting 4 12V lithium-ion batteries in series requires physical connections via additional cables and terminals. The quality, contact resistance, and oxidation resistance of these connections can affect overall performance.

Poor-quality connections can lead to voltage drops, energy loss, and even localized overheating and fire. Furthermore, frequent plugging and unplugging can cause connector wear, further reducing connection stability. The integrated 48V battery pack utilizes internal welding or high-reliability connections, requiring only a single external interface, significantly reducing connection failure points.

The Complexity of Charge Management

Different lithium battery chemistries (such as lithium iron phosphate and ternary lithium) require different charging algorithms and voltage parameters. When connecting 4 12V lithium batteries in series, a standard single-cell 12V lithium battery charger cannot be used. When selecting a suitable 48V charger, it is crucial to ensure that its charging parameters (especially the charging voltage) are fully compatible with the assembled battery pack.

A charging voltage that is too high can lead to overcharging, while a voltage that is too low can prevent the battery from being fully charged. Furthermore, a series configuration places higher demands on charge balancing. A standard 48V charger may not be able to effectively balance the charge between the 12V battery cells, leading to a significant degradation of battery performance over time.

Improper configuration poses safety risks

Lithium batteries have high energy density. If improperly configured, they can lead to overcharging, over-discharging, or short-circuiting, potentially causing thermal runaway and, in extreme cases, fire or explosion.

A series configuration increases system complexity and the probability of failure. Golf carts are often used outdoors, subject to environmental challenges such as vibration, humidity, and temperature fluctuations. These factors can easily lead to uncertainties in series connection.

The following summarizes the potential risks of configuring four 12V lithium batteries in series and a single 48V lithium battery pack to help you understand more clearly:

| Risk Type | 4 12V lithium batteries in series | Integrated 48V lithium-ion battery pack |

|---|---|---|

| Overcharge/Overdischarge Risk | High (each BMS operates independently) | Low-cost (unified BMS monitoring) |

| Connection Reliability | Low (multiple external connection points) | High-quality (internal integrated connections) |

| Charging Compatibility | Requires precise charger matching | Original charger |

| Environmental Adaptability | Impacted by multiple external interfaces | Sealed design for greater reliability |

| Long-Term Consistency | Gradually deteriorating | Excellent battery life |

Considering the aforementioned potential risks, while connecting 4 12V lithium-ion batteries in series theoretically provides a 48V voltage, practical applications present multiple challenges.

For golf cart owners who prioritize reliability and safety, this configuration presents significant risks. While a purpose-built 48V lithium-ion battery pack may incur a slightly higher initial investment cost, it is generally a more sensible option in terms of long-term performance, safety, and total cost of ownership.

If a series configuration is unavoidable, particular attention must be paid to battery consistency, connection reliability, and charging management. It is recommended that this be implemented under the guidance of a qualified professional.

Wiring Challenges for 48-Volt Golf Cart Battery Systems

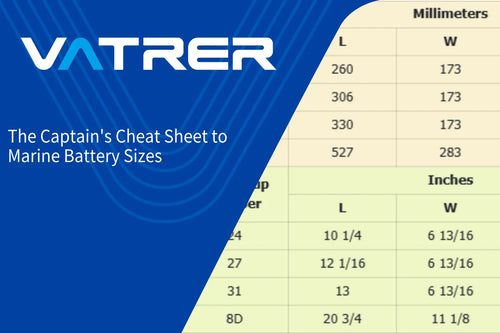

Creating a 48V system with 4 12-volt batteries requires a series connection, but many 48-volt golf carts are designed for 6 8-volt batteries or 4 12-volt batteries, making compartment fit a challenge.

Poor-quality connectors or loose terminals increase contact resistance, causing voltage drops or overheating. Vibrations from rough terrain can loosen terminals, raising resistance by 0.1Ω and reducing efficiency by 5%. Humid coastal areas accelerate connector corrosion, further impacting performance.

Wiring Tips:

- Use high-quality, corrosion-resistant connectors and tighten to 5-7Nm with a torque wrench.

- Inspect connections every three months for wear or oxidation, using a wiring diagram for 48-volt golf cart setups.

- Ensure proper ventilation to minimize humidity effects in battery compartments.

Will Using 4 12V Lithium Batteries Affect The Performance Of The Golf Cart?

Using four 12V lithium-ion batteries in series for a 48V golf cart raises questions about both technical feasibility and battery life. Understanding these implications can help you make cost-effective decisions and implement appropriate maintenance measures to extend the life of your battery pack.

Impact on the golf cart's battery life

The battery life of a lithium battery depends primarily on the total energy (Wh) of the battery pack, which is the product of voltage (V) and capacity (Ah). 4 12V, 100Ah lithium batteries connected in series to form a 48V system have a total energy of 4800Wh, the same as a single 48V, 100Ah battery pack. However, in actual use, series-configured battery packs often fall short of the expected battery life. The main reasons include: energy loss in the connection system, inconsistencies between battery cells leading to reduced capacity utilization, and coordination losses between independent BMS systems.

However, inconsistent battery performance can result in usable capacity of only 85%-90% of the nominal value, resulting in a 10%-20% reduction in range compared to a dedicated 48V battery pack.

Battery Pack Cycle Life

The lifespan of a lithium-ion battery is typically expressed as the number of charge and discharge cycles it undergoes under specific conditions before its capacity degrades to 80% of its rated capacity. High-quality lithium-ion batteries can achieve 2,000-5,000 cycles under ideal conditions.

However, the actual cycle life of multiple 12V lithium-ion batteries in a series configuration is often significantly reduced due to the difficulty in maintaining perfect balancing. Without effective balancing management, the actual cycle life of a four-cell 12V lithium-ion battery pack in series may be only 50%-70% of that of a single 48V lithium-ion golf cart battery, meaning you may need to replace the battery pack prematurely.

This approach is not cost-effective in the long term. In contrast, a single 48V lithium-ion golf cart battery pack with an integrated design uses a powerful battery management system to maintain balanced battery life, providing longer battery life.

Power output affects golf cart acceleration

The output power capability of a lithium battery is typically expressed in terms of the discharge rate (C-rate). For example, 1C means the battery can discharge its full capacity in one hour.

In a series configuration, if one 12V battery has high internal resistance or poor performance, it can become a bottleneck for the entire system, limiting the maximum output current.

This limitation is particularly noticeable when a golf cart needs to accelerate rapidly or climb a hill, and you may experience a lack of power. Furthermore, uneven current distribution can cause some batteries to operate at elevated temperatures, further accelerating performance degradation. 48V power battery packs designed specifically for golf carts typically utilize cells with lower internal resistance and optimized heat dissipation, providing stronger and more stable power output to meet the diverse operating conditions of golf carts.

Uneven Temperature Management

This phenomenon is more pronounced in configurations with multiple batteries connected in series. The performance and lifespan of lithium-ion batteries are closely related to operating temperature, with the ideal operating temperature range typically between 59-95°F (15-35°C). When 4 12V lithium-ion batteries are installed in a vehicle, they may be exposed to varying temperatures depending on their location. For example, batteries near the motor may run hotter than those located elsewhere. This temperature difference can lead to variations in parameters such as internal resistance and self-discharge rate, impacting the consistency of battery charge and discharge behavior. However, integrated 48V battery packs typically utilize a shared heat dissipation structure and temperature-homogenizing design, maintaining a more consistent temperature environment for each individual battery, which is beneficial for overall performance.

To help you understand more clearly, the table below summarizes the performance comparison of using four 12V lithium batteries in series in a golf cart and an integrated 48V lithium battery pack to help you choose the battery that is more suitable for you.

| Performance Indicators | 4 12V lithium batteries in series | 48V lithium battery | Variance Analysis |

|---|---|---|---|

| Actual usable capacity | Approximately 85%-90% of nominal value | Approximately 95%-98% nominal value | Poor consistency in series configurations leads to low capacity utilization |

| Cycle life | Approximately 1,000-2,500 cycles | Approximately 2,000-5,000 cycles | Balancing issues significantly impact the lifespan of series configurations |

| Peak power output | Limited by the weakest battery | Overall optimized design | Series configurations may create power bottlenecks |

| Temperature uniformity | Poor (depending on installation location) | Excellent (shared heat dissipation) | Temperature differences exacerbate inconsistencies in series battery configurations |

What Are Some Alternative Solutions For 48V Golf Cart Batteries?

Given the technical challenges and performance issues of using 4 12V lithium batteries in a 48V golf cart, instead of using 4 12V batteries, consider the following alternatives to achieve better performance and safety:

Buy a Dedicated 48-Volt Lithium Battery Pack

Single 48-volt lithium battery packs, such as the Vatrer 48V 150Ah battery, suitable for multiple rounds of 18-36 holes of golf, with over 4,000 cycles, or the Vatrer 48V 105Ah battery, ideal for budget-conscious recreational vehicle owners, all offer an integrated BMS and simplified installation. These battery packs are designed specifically for Club Car Precedent, EZGO, Yamaha, and ICON golf cart battery systems, ensuring compatibility and reliability.

Explore Hybrid Parallel-Series Configurations

Some high-end lithium-ion battery manufacturers have introduced modular battery systems, allowing users to flexibly combine battery cells to meet their specific needs. For example, the Vatrer battery design allows users to connect two batteries in parallel to increase capacity, then connect them in series to achieve the desired voltage. This configuration maintains better battery consistency than a simple series connection because the parallel cells automatically balance.

For use in a 48V golf cart, you can connect 2 24V lithium-ion batteries in series. Each 24V battery consists of 2 12V batteries connected in parallel. This reduces the number of series cells and minimizes the risk of imbalance.

However, it is important to note that this configuration still requires specially designed battery modules and a supporting management system. Not all 12V lithium-ion batteries support this connection method, so consult a professional technician before implementing it. A golf cart system expert can provide guidance on optimal battery selection and ensure a safe and efficient installation.

Conclusion: Choosing the Best Battery System for Your Golf Cart

While it's theoretically possible to equip a 48-volt golf cart with 4 12-volt batteries, issues with wiring, battery consistency, and controller compatibility when connecting multiple batteries make it a less-than-optimal option.

Using a dedicated 48-volt lithium-ion battery pack can improve efficiency, extend lifespan, and enhance safety for your golf cart.

If you're considering replacing or upgrading your cart's power battery, the Vatrer 48V 105Ah lithium-ion battery is 50% lighter than lead-acid batteries and supports fast charging. Designed specifically for Yamaha, EZGO, and Club Car golf carts, it offers over 3,000 cycles, making it ideal for golf courses or recreational use. Explore the Vatrer lithium-ion golf cart battery lineup and choose the battery that best suits your needs.

1 comment

Stevde

I would to convert my ezgo cart 36 to 48v is it possible

I would to convert my ezgo cart 36 to 48v is it possible